Jewellery Making Strips

Jewellery Strips For Every project

Jewellery making strips are essential materials that bring versatility and creativity to your designs. At Ore Metals, our collection of jewellery making strips includes a variety of forms such as bezel strips, gallery strips, cloisonné strips, and embossed strips. These strips are available in high-quality metals like sterling silver, solid gold, 24k fine gold, and 9999 fine silver, offering both aesthetic appeal and durability. Whether you are crafting intricate settings, detailed patterns, or custom embellishments, our strips provide the perfect foundation for your unique creations.

Types of Jewellery Making Strips and Their Applications

Our collection features a wide range of jewellery making strips, each tailored for specific applications:

- Bezel Strip: Bezel strips are a cornerstone in stone setting, providing a secure and elegant way to encase gemstones. Available in sterling silver and solid gold, our bezel strips come in various sizes and styles, allowing for precise customization to fit stones of different shapes and sizes. These strips ensure a snug fit around the gemstone, enhancing both the security and the overall aesthetic of the piece.

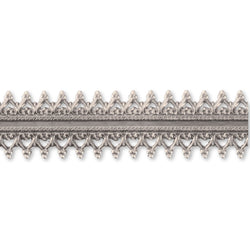

- Gallery Strip: Gallery strips are designed to add intricate, decorative elements to your jewellery. Available in sterling silver and multiple styles, these strips are perfect for creating ornate borders and adding texture to your designs. Their openwork patterns allow light to pass through, creating a delicate and visually appealing effect that enhances the beauty of your jewellery pieces.

- Cloisonné Strip: Cloisonné strips, available in 24k fine gold and 9999 fine silver, are ideal for the ancient art of cloisonné enamelling. These strips are used to create the raised partitions that define the design areas on enamel work. The purity of the metals ensures that they fuse perfectly with the enamel, resulting in a smooth, polished finish that is both vibrant and durable.

- Embossed Strips: Our embossed strips come in a wide range of patterns and styles, offering endless possibilities for adding texture and detail to your jewellery designs. These strips can be used as decorative elements on rings, bracelets, and other jewellery pieces, providing a unique, handcrafted look that stands out. The patterns range from classic to contemporary, allowing you to find the perfect match for your design aesthetic.

Benefits of Using High-Quality Jewellery Making Strips

Using high-quality jewellery making strips from Ore Metals ensures that your designs are both beautiful and durable. Our strips are manufactured to precise standards, providing consistent thickness and flexibility, which is crucial for achieving professional results. Whether you’re setting a gemstone with a bezel strip or adding decorative details with an embossed strip, the superior quality of our materials ensures that your work will stand the test of time. Additionally, the use of precious metals like solid gold and silver adds intrinsic value to your creations, making them more desirable to customers.

Tips for Working with Jewellery Making Strips

Working with jewellery making strips requires a blend of skill and attention to detail. When using bezel strips, ensure that you measure and cut the strip precisely to fit the stone snugly. Solder the ends carefully to avoid gaps, which could compromise the setting's security. For gallery strips, pay attention to the pattern alignment, especially when creating symmetrical designs. When working with cloisonné strips, it’s essential to maintain the integrity of the partitions during the enamelling process to ensure a clean, crisp design. With embossed strips, consider how the pattern will complement the overall design of the piece, and use tools that will preserve the detail of the embossing during shaping and soldering.

Customization and Creative Possibilities

The variety of jewellery making strips available at Ore Metals opens up endless creative possibilities. By mixing and matching different types of strips, you can create truly unique and personalised pieces. For example, combining a bezel strip with an embossed strip can result in a striking contrast between the smooth bezel and the textured pattern. Using gallery strips in conjunction with cloisonné strips can add an extra layer of intricacy to your enamel work. The flexibility of these strips also allows for easy customization, enabling you to adjust the size, shape, and design to fit your creative vision perfectly.

Frequently Asked Questions

Bezel strips are a jeweller's staple for crafting custom settings that hold precious stones securely in place.

They are made from high-quality silver and gold alloys, offering both strength and malleability to wrap around stones of any size, creating a seamless and elegant setting that is both functional and attractive.

By incorporating bezel strips artisans can ensure their gemstones are showcased beautifully and safely.

Gallery strips add a touch of elegance and intricacy to jewellery designs. These decorative metal strips, available in 925 sterling silver, feature ornate cut-outs and patterns that are perfect for edging pieces or adding decorative elements.

By using gallery strips from our extensive range of jewellery making supplies, designers can elevate their creations with detailed borders that catch the light and add an element of sophistication to any piece.

Absolutely! Our embossed strips are designed to add depth and texture to your jewellery, and they can be further customized to fit your specific project needs.

With a variety of patterns available, these strips are perfect for creating standout pieces that require a tactile element.

Whether you're looking to add a bold feature or subtle detail to your creations, our embossed strips are a versatile choice that can be shaped and trimmed to suit your design vision.

Cloisonné strips are essential for creating the refined and colourful enamel work known as cloisonné, a celebrated technique in jewellery making.

These fine metal strips, available in both Fine silver and Fine gold, are skilfully bent into intricate designs and soldered onto jewellery bases, acting as dividers that will later be filled with enamel to create vibrant, detailed patterns.

Our cloisonné strips provide craftsmen & craftswomen with the high-quality material needed to achieve the precision and durability required for exquisite cloisonné artistry.

Bezel strip, also known as bezel wire is a thin piece of metal, typically sterling silver, pure silver or 9ct / 18ct gold, used to create a bezel setting around a gemstone. This strip is shaped and soldered to form a secure frame that holds the stone in place, ensuring durability and protection.

To use bezel wire for gemstone setting, first measure and cut the strip to fit snugly around the stone. Solder the ends together, shape the bezel around the stone, and then solder the bezel to the jewellery piece. Finally, use a bezel roller to gently push the wire over the stone's edges, securing it in place.

The thickness of bezel wire for cabochons typically ranges from 0.3mm to 0.5mm (28 to 24 gauge). Thicker wire provides more durability and is ideal for larger or heavier stones, while thinner wire is easier to work with and better for smaller stones.

Yes, bezel strips can be used for setting faceted stones. The bezel setting provides a sleek, modern look and securely holds the stone in place, protecting its edges. Ensure the bezel strip is thin enough to fold over the stone without obscuring its facets.

A gallery strip in jewellery making is a decorative metal strip with intricate cut-out patterns. It is used to create elegant settings for gemstones, adding both structural support and visual interest to rings, pendants, and other jewellery pieces.

Bezel wire is a solid strip of metal used to create a simple, smooth frame around a gemstone. In contrast, gallery wire is more decorative, featuring openwork patterns that add intricate details to the setting while still holding the stone securely.

To solder bezel wire without melting it, use a low-temperature solder and apply heat gradually with a torch, focusing on the area where the solder is applied. Keep the flame moving to avoid overheating any one spot, which could cause the wire to melt

Bezel strips are available in various metals, including sterling silver, fine silver, 9ct, 14ct, and 18ct gold. These options allow jewellers to choose the best metal for their design and gemstone.

Choose the right gallery wire for your project by considering the size and style of your gemstone and the overall design. For intricate designs, select a gallery wire with finer patterns. Ensure the height of the gallery wire matches the depth of the gemstone.

Gallery wire is commonly used to create decorative bezel settings for gemstones, add embellishments to jewellery pieces, and serve as an ornate edge or frame in rings, pendants, and bracelets. It enhances the visual appeal while securing the stones.

Yes, gallery wire can be used for both rings and pendants. Its versatility and decorative patterns make it suitable for various types of jewellery, allowing for cohesive designs across different pieces.

Gallery strips are available in a wide range of patterns, including floral, geometric, and lace-like designs. These patterns can vary in intricacy and size, offering options for different styles and gemstone shapes.

To secure gemstones with gallery wire, solder the wire to the jewellery base or back plate, place the gemstone inside the gallery setting, and gently push the prongs or edges of the gallery wire over the stone using a bezel roller, bezel pusher, prong pusher or a combination of all 3. Ensure the stone is held firmly without being overly tight.

A cloisonné strip is a thin metal strip used to create partitions or cells in the cloisonné enamelling process. These strips are soldered onto a metal base, and the resulting cells are filled with enamel powder and fired, creating vibrant, intricate designs.

Cloisonné strips are typically made from high-purity metals such as 24k fine gold and 9999 fine silver. These metals are chosen for their ability to withstand the high temperatures of the enamelling process and their excellent compatibility with enamel.

To prepare cloisonné wire for enamel work, clean the wire thoroughly to remove any oils or residues. Shape the wire into the desired design, solder it to the metal base, and ensure all connections are secure before applying enamel.

Best practices for soldering cloisonné strips include using a fine-tipped torch for precise heat control, applying a thin layer of flux to prevent oxidation, and soldering quickly to avoid damaging the delicate wire. Always clean the piece thoroughly before adding enamel.

The right cloisonné wire thickness depends on the design complexity and the depth of the enamel you plan to use. Typically, cloisonné wire ranges from 0.25mm to 0.5mm in thickness, with thinner wires being better for intricate designs and thicker wires providing more structural support.

Yes, cloisonné strips can be used with other types of wire, such as bezel or gallery wire, to create mixed-media jewellery pieces. Combining different wires can add texture and dimension to your designs, making them more unique and visually interesting.

An embossed strip in jewellery making is a metal strip that has been patterned or textured through a stamping or rolling process. These strips are used to add decorative elements to jewellery pieces, such as rings, bracelets, and pendants, providing a rich, textured finish.

The advantages of using embossed strips in jewellery include adding visual interest, enhancing the tactile quality of the piece, and allowing for intricate designs without the need for extensive hand engraving. Embossed strips are also available in various patterns, making them versatile for different styles.

To solder embossed strips without losing the pattern, use a lower-temperature solder and heat the piece gradually. Apply heat evenly and focus on the solder joint, avoiding direct flame contact with the patterned surface. A heat-resistant paste or soldering block can help protect the embossing during soldering.

Embossed strips are available in a wide range of patterns, including floral, geometric, and abstract designs. These patterns vary in depth and intricacy, allowing you to choose the perfect strip to complement your jewellery design.

Yes, embossed strips can be used for making rings. They add a decorative element to the band, creating a unique, textured look. Ensure the strip is properly sized and shaped before soldering to create a seamless, comfortable ring

There is no difference between decorative wire and patterned wire; they are simply different names for the same product. Both terms, along with "embossed strip," refer to wire or metal strips that have been mechanically embossed with a pattern or texture. These products are used interchangeably in jewellery making to add visual interest and texture to designs.

To create custom designs with patterned wire, select a wire pattern that complements your overall design. Use the wire to outline or accentuate key elements of your jewellery piece. You can also combine different patterned wires to create a unique, layered effect

Some of the most popular decorative wire patterns include floral and geometric patterns. These patterns add texture and dimension to jewellery pieces

Yes, decorative wire can be used for structural components in jewellery, provided it is thick and strong enough to support the design. For example, a thicker patterned wire can be used as the main band in a ring or as a sturdy frame for a pendant.

The right thickness of embossed strip depends on the design and function of the jewellery piece. Thicker strip (18-20 gauge) is ideal for structural elements, while thinner strip (22-26 gauge) is better for decorative accents and finer details.

Patterned wire is available in sterling silver, with some variations available in 9k and 18k gold.

Working with bezel strips requires a few tools, including:

Flush cutters: For cutting the bezel strip to the correct length.

Soldering setup: Including a torch, flux, and solder, for joining the ends of the bezel.

Bezel roller or burnisher: To smooth and secure the bezel around the gemstone.

Files and sandpaper: For smoothing edges and finishing the bezel. These tools help you create precise and secure bezel settings for gemstones in your jewellery designs.

To clean and maintain jewellery made with cloisonné strips, use a soft, lint-free cloth to gently wipe the surface, removing any dust or oils. For deeper cleaning, use warm water mixed with a mild soap, and gently clean the piece with a soft brush. Avoid abrasive cleaners or chemicals, as they can damage the enamel or metal. Store cloisonné jewellery in a dry, soft-lined box to protect it from scratches and humidity. Regular maintenance will keep the enamel vibrant and the metal lustrous.

The best way to store unused bezel and gallery wires is to keep them in a cool, dry place, away from direct sunlight. Pack the wires neatly to prevent kinks or bends, and store them in labelled plastic bags or compartments to keep them organised and free from dust. Consider storing them in anti-tarnish bags or adding anti-tarnish strips to the storage area to prevent oxidation. Proper storage will maintain the quality and usability of the wires for future projects.

To bend and shape bezel wire without damaging it, use the appropriate tools (Bezel Roller, Bezel Pusher) for precise control, and work slowly to avoid kinks or warping. If the wire is thick or hard, anneal it first by heating it with a torch and allowing it to cool, which makes it more pliable. Always bend the wire gradually and use a mandrel or shaping tool to achieve smooth curves. This technique helps preserve the integrity of the wire while creating the desired shape for your jewellery.

The best solder for working with fine silver and gold cloisonné strips is an enamelling solder. enamelling solder has a high melting point that provides a strong, durable bond, which is important for maintaining its structure during the enamel firing process.

To avoid warping when soldering bezel strips, evenly heat the entire piece rather than focusing the flame on a single spot. Use a soldering block to support the bezel strip and distribute heat more uniformly. Additionally, anneal the metal before soldering to relieve internal stresses that could cause warping. Applying solder sparingly and allowing the piece to cool gradually will help maintain the bezel strip's shape.

The best gauge of wire for making bezels typically ranges from 26 to 28 gauge (0.4mm to 0.3mm). This thickness provides the right balance of flexibility and strength, making it easy to bend around a gemstone while still securely holding it in place. For larger or heavier stones, you might opt for a slightly thicker bezel wire, such as 24 gauge (0.5mm), to ensure durability.